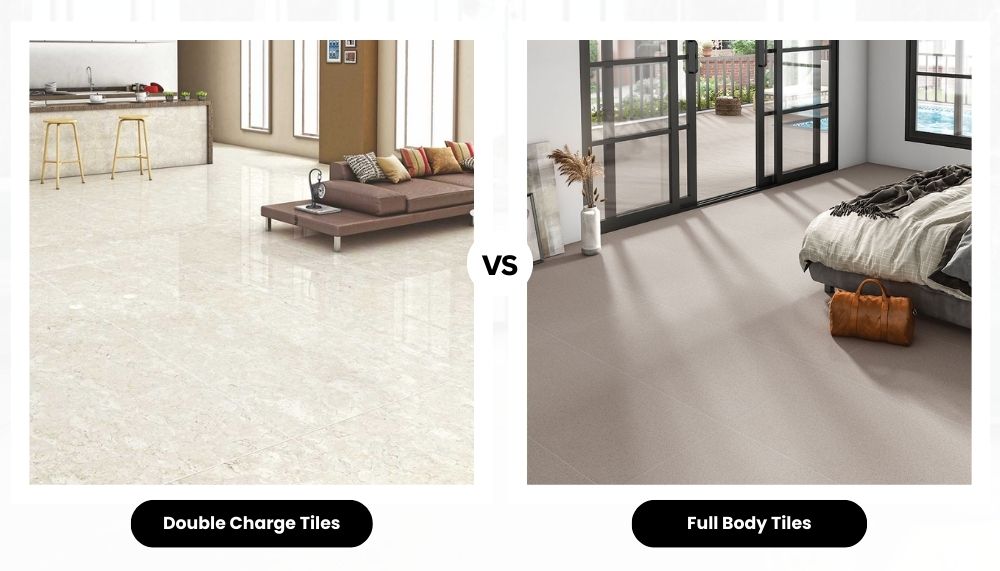

Tiles are a crucial element of modern interiors, and selecting the right type can elevate a space's overall aesthetic and functionality. Double-charge (DC) and full-body vitrified tiles are two of the most popular types.

While both share similarities, their manufacturing process, design options, and durability set them apart. Here's a detailed comparison to help you make an informed choice.

9 Common Differences Between Full Body Vitrified Tiles and Double Charge Tiles

1. Manufacturing Process

Double Charge tiles are produced using a hydraulic press that combines two layers. The upper layer, about 3-4 mm thick, consists of rugged textures. This layer ensures the tiles are vibrant and highly durable. The process involves pressing the tiles in molds to achieve a uniform finish.

In contrast, full-body vitrified tiles are made using high-pressure technology. A pressure of 450 bars - 550 bars is applied on the surface, followed by high-resolution printing. The main thing is that it has homogenous coloring throughout the tile and has high thickness making it durable and robust.

2. Printing

Double Charge tiles have their designs created through colored textures applied during the pressing process. These designs penetrate up to 3-4 mm into the tile, ensuring they remain visible even after significant wear. However, design variety is limited due to the use of fixed molds.

Full body vitrified tiles, on the other hand, are printed using inkjet technology, allowing for endless customization options making it the cherry on the cake on its uniformity of material and color throughout the tile feature. The printed layer is less than 1 mm thick, making it suitable for intricate patterns and unique textures.

3. Calibration and Polishing Machines

Double Charge tiles go through an extensive finishing process. After cooling, they are passed through calibration machines that use diamond rollers to achieve a smooth surface. Polishing and sizing machines are also employed to provide a glossy finish and uniform dimensions.

Full-body vitrified tiles, especially those with a matte finish, require less polishing. They are processed using sizing machines to ensure consistent dimensions. The restricted use of polishing machines contributes to their matte and natural look.

4. Design

Design options for double-charge tiles are somewhat limited. Fixed molds and feeders restrict the variety, making these tiles suitable for less emphasis on intricate aesthetics. Customization is not feasible, but they offer consistency in patterns and colors.

Full-body vitrified tiles shine when it comes to design versatility. Advanced digital printing allows these tiles to replicate natural stone, wood, or any artistic pattern. Their ability to be customized according to specific interior themes makes them highly popular for creative designs.

5. Life Span

In contrast, double-charged tiles have a thinner but two-layered surface making it high resistance to scratches and chips. So they are perfect for high-traffic commercial areas & offer a longer life span. However, they are less suitable for low-traffic areas and areas with extreme temperature fluctuations.

On the other hand, full-body tiles have a longer lifespan due to their thicker upper layer. Even with heavy usage or minor damage, the design layer remains intact. This durability makes them ideal for medium to high-traffic areas.

6. Usage

Double-charged tiles are designed for durability, making them a preferred choice for high-traffic areas like malls, airports, hospitals, and office spaces. Their robust nature ensures they withstand wear and tear effectively.

Where full-body vitrified tiles are less suitable for extremely high-traffic environments. They are commonly used in homes, boutique offices, and some commercial areas where aesthetic appeal is prioritized over extreme durability.

7. Price

The cost of double-charge tiles is slightly higher in price due to their manufacturing complexity and thicker pigment layer. For example, 600×600 mm tiles range from ₹25 to ₹35 per square foot (ex-factory). Special patterns and colors can increase the price.

Full-body vitrified tiles are also comparatively the same but a bit lower, with prices for 600×600 mm tiles starting at ₹23 per square foot. Larger sizes and unique designs may cost more but remain within an economical range. Additional charges like transportation and unloading should also be considered.

8. Available Sizes

Double Charge tiles are commonly available in standard sizes such as 600×600 mm, 600×1200 mm, and 800×800 mm, making them ideal for uniform layouts.

Full-body vitrified tiles, however, offer more size options, including 600×600 mm, 600×1200 mm, 800×800 mm, 800×1200 mm, and even larger formats like 1200×1600 mm. This variety provides more flexibility for creative floor and wall designs.

9. Durability

Durability is a key advantage of double-charged tiles. The thicker upper layer provides better resistance to scratches, stains, and general wear, making them suitable for high-traffic and heavy-duty applications.

Full-body vitrified tiles, while durable, are less robust than full-body tiles. The thinner glaze layer is prone to fading or damage in high-traffic environments, limiting their application to less demanding spaces.

Quick Summary

| Aspect | Double Charge Tiles | Full Body Vitrified |

| Manufacturing Process | Two-layered with 3-4 mm pigment upper layer. | Single-layered with a thin glaze & homogenous coloring throughout the tile |

| Printing | Designs created using color pigments and molds. | Printed digitally with endless customization options. |

| Calibration & Polishing | Calibrated, polished, and sized for a glossy finish. | Only sized; no polishing required for matte finishes. |

| Design | Limited patterns and fixed designs. | Wide variety of customizable designs and textures. |

| Life Span | Longer lifespan due to thicker upper layer. | Shorter lifespan compared to double-charge tile. |

| Usage | Suitable for high-traffic areas like malls and airports. | Ideal for medium to high-traffic spaces like homes. |

| Price (600×600 mm) | ₹25–₹35 per sq. ft (ex-factory). | ₹23–₹28 per sq. ft (ex-factory). |

| Sizes Available | Standard sizes like 600×600, 600×1200, 800×800 mm. | More options include 800×1200 and 1200×1600 mm. |

| Body Structure | Dual layer: durable upper and base layer. | Single-layer with a full-body surface. |

Conclusion

Both double-charge and full-body vitrified tiles have unique strengths that cater to different needs. Double-charge tiles are ideal for those seeking durability and a premium marble-like appearance for high-traffic areas. On the other hand, full-body vitrified tiles excel in customization, offering endless design possibilities for residential and low-traffic spaces.

The choice between the two ultimately depends on your budget, style preferences, and intended application. Understanding these differences ensures the perfect tile selection for your project, whether you prioritize longevity or creative design.

You May Also Like: